✓

Azumuta

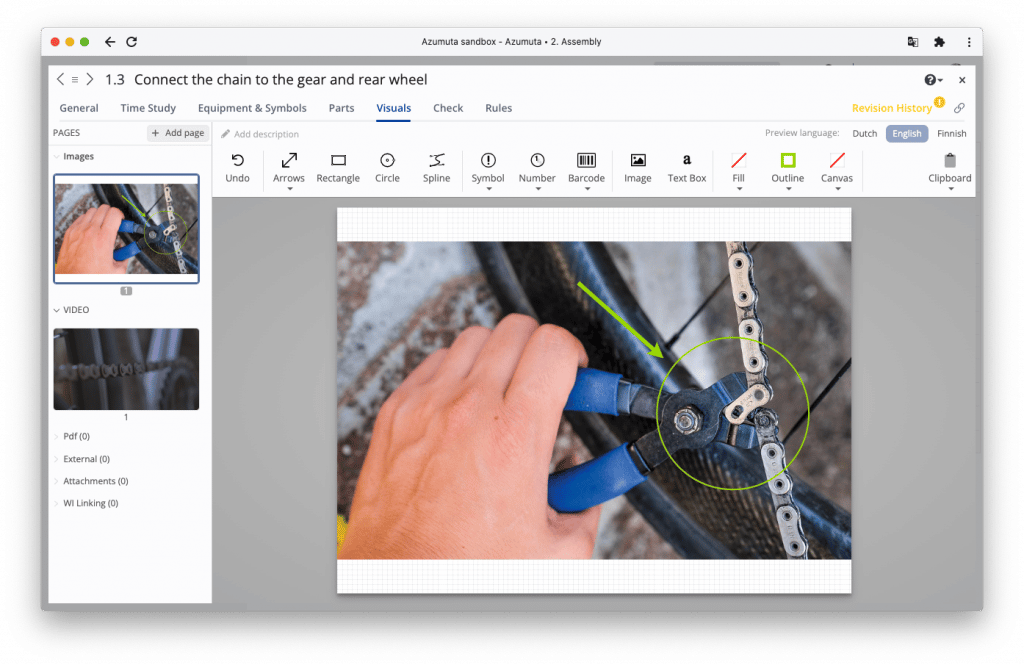

Manage the knowledge, training and communication of your factory with our fully integrated platform.

Azumuta assists manufacturing companies with driving performance by enabling factory workers to learn, solve issues and offer information progressively on the factory floor. Our software connects operators, supervisors and managers to every single manufacturing aspect, and supports a culture of constant improvement. Azumuta is a modular online platform that helps people in a factory environment to increase productivity and quality of production by better communication and technological support. The origin of the word "Azumuta" is unclear, some think its origin lies in the Japanese word (始めた) for "I started" and resembles several values: An action, a fresh beginning, a personal commitment and responsibility, self assurance, and hope. Others think it comes from the Flemish word (Azo moeta, zo moet dat / aha, zo moet dat)

- Paid

- Free Trial

- €500.0 / Monthly

- Official Pricing

- Browser

- Android

- iOS

- Google Chrome

- Firefox

- Safari

- Web

- REST API

- Edge